Applications

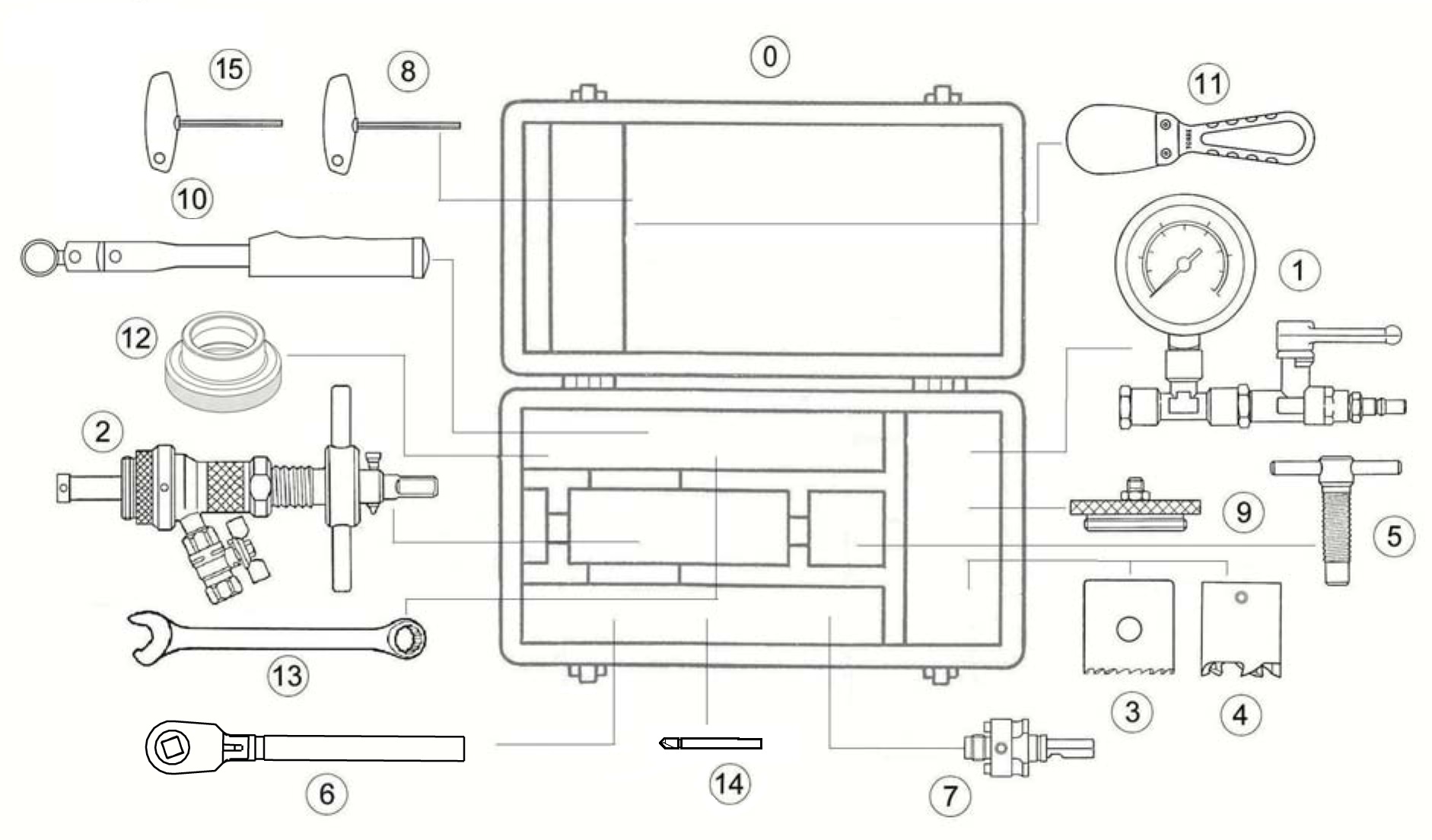

Under pressure drilling equipment (EP16) includes all elements necessary to install service connection collars and carry out drilling for subsequent launching on polyethylene, ductile iron, cast iron and steel pipes.

Advantages

Drilling equipment is prepared to make any drilling. Moreover it ensures complete gas-tightness, avoiding gas leaks and allowing working under maximum safety and effectiveness.

Equipment box

Equipment box is made of PVC layered board, anodized aluminium edge protection and lock with key. The inside is divided into compartments for correct equipment storage.

Drilling tool

Drilling tool is completely manufactured of hardened steel. The compact design of this drilling tool makes it ideal for use in places with restricted accessibility. Drilling tool is supplied with manual operating ratchet wrench or with an electric, pneumatic or hydraulic motor. The thrust screw incorporates brackets for hand activation.

Leak-tightness test

A cover is supplied with the equipment for leak-tightness test, prior to drilling, to verify that the seal between the collar and the pipe is 100% tight.

Mechanic collar tighten

Under pressure drilling equipment provides a fixed torque wrench to properly tight the straps.

Equipment maintenance

To keep the equipment in good working order, it is advisable to carry out an annual check in the factory.

Identification

All the equipment bears an identification number and label to keep track of the revisions carried out.